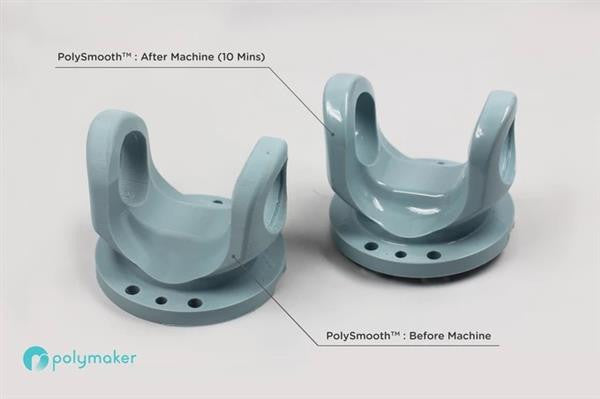

AN ENTIRELY NEW 3D PRINTING FILAMENT & DESKTOP MACHINE, TO DRAMATICALLY IMPROVE THE SURFACE QUALITY OF 3D PRINTED PARTS.

PolySmooth™

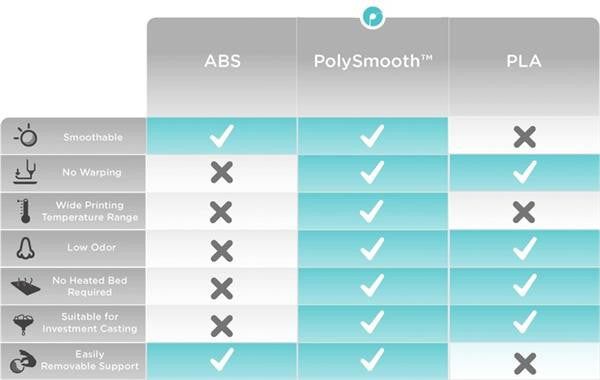

FeaturesPolishable: The first 3D printable filament engineered for layer free post-processing. We have specifically developed PolySmooth™ to work alongside the Polysher™ providing the solution to dramatically improve the surface quality of 3D printed objects. Easy to Print: PolySmooth™ is compatible with all filament-based 3D printers and prints under similar conditions as PLA. Featuring a wide printing temperature range, low odor and no heated bed required, PolySmooth™ is the perfect companion to your desktop 3D printer. Optimized for Support: We have taken our experience from PolySupport™ and engineered PolySmooth™ with the same support removal properties. Easily break away support from PolySmooth’s™ surface and once your model is polished there is no scar left on the surface. Balanced Mechanical Properties: PolySmooth™ features well balanced mechanical properties, outperforming ABS and PLA on most attributes , making it an ideal material for everyday 3D printing. Warping Free: PolySmooth™ exhibits very minimal residual stress when printing which means almost no warping, making it ideal for printing large parts.

CLICK HERE TO ORDER NOW - Polysmooth Filaments |

Polysher™

The Polysher™ was designed with a methodical approach from the electronics to the bolts used, With over 40 parts, our designers made sure nothing was overlooked ensuring accurate designs and well thought out manufacturing.

FeaturesIntuitive & Easy To Use: Simply twist the dial to set the time, sit back and watch the magic happen. Built-In Safety Features: The Polysher™ was designed with smart electronics,air tight seals and more. Low Costs: The Polysher™ is not only affordable but its running cost is incredibly low too.

CLICK HERE TO ORDER NOW - Polysher Unit |

FAQ

Does the Polysher work with Acetone?

No. The Polysher is only uses alcohol or alcohol solutions (with concentrations of 70% or higher) as the polishing liquid. Do not use acetone with the Polysher, Polymaker do not recommend other liquids/solvents other than isopropanol or ethanol. This will damage the unit and void your warranty.

Can I smooth my PLA and ABS printed parts?

The Polysher is designed to only work with an Alcohol Soluble filament like PolySmooth PVB. PLA and ABS are not polishable with alcohol.

Is the Polysher a 3D Printer?

No, the Polysher is not a 3D printer, you will still need an FDM extrusion based machine to use this product.

What size parts can I smooth with the Polysher?

You can smooth parts up to a 150mm diameter x 180mm height cylinder.

Is the Polysher Safe?

The short answer is yes. Polymaker have taken many steps to ensure their technology is safe. No heating is involved. The nebulizer technology requires only a very small reservoir. It is a liquid-phase polishing rather than vapor-phase polishing process (the latter is more dangerous for a number of reasons)

Polymaker have also implemented a number of safety features into the machine: Multiple sensors to detect any sign of malfunction of the nebulizer (e.g. running dry) as well as a Chamber open/close sensor (the machine won’t start if the chamber is open, and will automatically terminate if the chamber is accidentally open during polishing.)